Quick Summary:

Getting certified to operate a forklift isn’t just about learning how to drive — it requires passing an OSHA forklift evaluation test, which includes a written exam and a hands-on skills exam.

Learn what’s included on each portion of the exam, what topics to study, and how to prepare so you can pass your forklift certification test and stay compliant.

About OSHA Forklift Certifications

All forklift operators are required by law, according to OSHA act 29 CFR 1910.178(I), to pass a forklift certification test before handling any industrial power machinery. The test evaluates the operator’s knowledge of safety protocols and their ability to operate a forklift truck properly.

There are 3 steps to becoming a certified forklift operator:

- Formal instruction: First-time certifiers must complete a course online or in person at a trade school or local OSHA-approved program. Recertifiers can take a quick refresher course online.

- Practical training: Supervised, hands-on use of a forklift.

- Performance evaluation: Includes a written test and a driving/operating evaluation.

We’ve created this guide to help you learn what topics could be covered on each part of your forklift operator test so that you can prepare and feel confident before taking your exam.

Part 1: The Written Test

The first part of the forklift operator test is the written knowledge portion. This section tests your understanding of forklift specifications, parts, controls, and safety in a series of multiple choice questions.

It’s the only part of the exam that can be taken online, and can take anywhere from 20-30 minutes to complete. Operators must score a 70% or higher to pass.

Below are some examples of concepts you could be tested on during the forklift written exam:

Machine Specifications

You’ll be tested on your knowledge of the machine you’ll be operating on, which includes:

- The data plate: the model, weight, and maximum lifting capacity of the machine.

- The load center: the distance from the vertical face of the forks to the load’s center of gravity.

You’ll also be tested on your knowledge of additional operating principles, like

- The center of gravity (CG): the combined CG of the forklift and the load.

- The stability triangle: an imaginary triangle with three points – the two front wheels and the center of the rear axle – that the CG must stay inside to remain stable.

You should also be able to explain the different types of tires and their uses and the differences between electric vs. gas/propane forklifts.

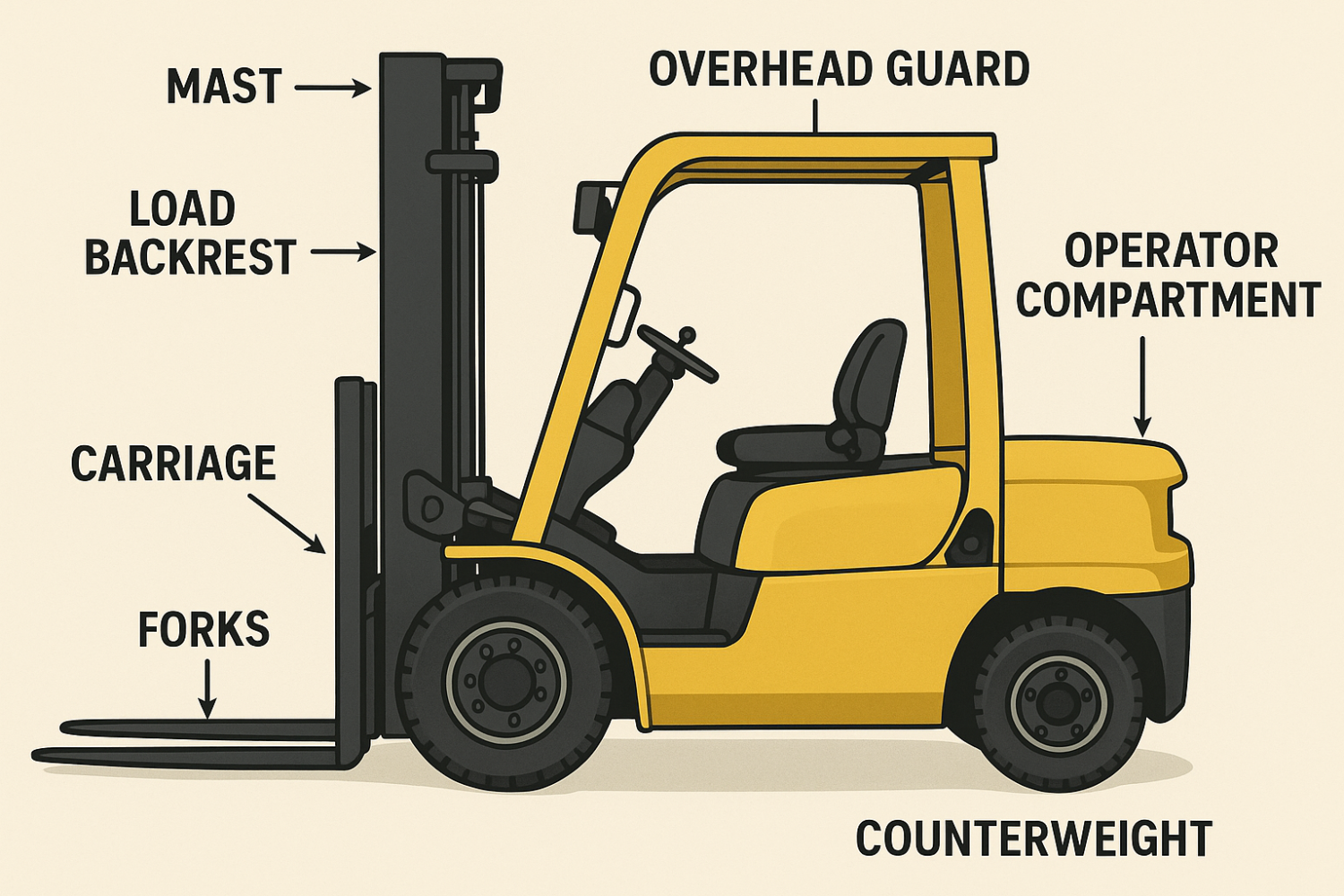

Forklift Parts & Controls

You might also be asked questions about the basic parts of the forklift – where they are located, their purpose, and their controls.

Key parts and controls:

- Mast: the vertical mechanism that raises and lowers the load; moves forward and back using the tilt lever.

- Forks: the metal “arms” that carry the load; raised and lowered using the lift/lower lever.

- Carriage: the piece where the forks are attached. If equipped with a side-shifter, this control moves the carriage slightly to the left and right for minor adjustments.

- Overhead guard: the roof of the operator’s cab, intended to protect the operator from falling objects.

- Accelerator and brakes: the start and stop pedals; operated just like in a car.

- Parking brake: prevents accidental movement when the operator needs to leave the cab; engaged by pulling a lever or pushing a button.

Operator Safety

Operator safety is another huge part of the written forklift certification test. Many of these rules are intuitive – always wear your seatbelt, keep your body inside the cab at all times, always wear your personal protective equipment (PPE).

You could also be tested on elements, such as:

- Visual and operational pre-shift inspection requirements.

- Forklift traffic rules and signage.

- Safe handling instructions for operating on ramps and inclines.

- Rules for operating on specific use cases – on loading docks, in narrow aisles, and on ramps or inclines.

- Refueling and battery charging safety.

Emergency Procedures

The written portion may also include some “what-if” scenarios to gauge your understanding of how you should react when an emergency occurs.

In the event of a:

- Tip-over: do not jump. Stay seated and brace for the fall. Hold the steering wheel, brace your feet, and lean away from the direction of the fall.

- Fire: know where the extinguisher is located. Park the forklift, lower the forks, turn off the machine, and proceed using your site’s evacuation plan.

- Mechanical failures: Stop the forklift, lower the forks, pull the parking brake, turn off the machine, and report the failure immediately. Do not operate the machine again until it’s fixed.

These procedures are enforced to keep operators safe when unanticipated problems occur during machine handling.

Part 2: The Practical Evaluation

After passing the written part of the forklift certification test, the next step is to complete the on-site evaluation using the actual forklift model you’ll be operating. A qualified trainer (usually your employer) will observe your performance and determine your skill-level based on a series of operational tests.

You’ll be observed on non-tangible safety skills and machine-handling abilities.

| Safety Skills | Machine-Handling Skills |

|---|---|

|

|

If you demonstrate unsafe behavior or lose control of the machine during the practical evaluation, you will not pass this portion of the test.

Certification Test Variations By Equipment Type

Different forklift models have different operating controls and requirements, which means certification tests can vary based on the type of material you’ll be handling.

The main differences on the written test includes questions about forklift controls, fueling/charging specifications, and specific operational characteristics.

| Forklift Class | Written Test Variations |

|---|---|

| Class I, II, & III – Electric Trucks |

|

| Class IV & V – Gas/Propane Trucks |

|

| Class II – Narrow Aisle Trucks |

|

| Class III – Pallet Jacks/Hand Trucks |

|

The main differences between the practical test requirements is focused on the operator’s ability to handle the specific characteristics of each forklift.

| Forklift Class | Practical Test Variations |

|---|---|

| Class I, IV, & V – Sit-Down Counterbalanced Forklifts |

|

| Class I & II Stand-Up – Counterbalances & Narrow Aisle Forklifts |

|

| Class III – Electric Pallet Jacks & Stackers |

|

Make sure your evaluation is based on the specific type of powered industrial truck you’ll use.

IFT: Your Certification Resource

At IFT, we help you understand every step of the forklift certification journey. While we don’t offer training or testing directly, our resources break down OSHA certification standards, help you prepare for your exam, and offer insights into forklift maintenance and ownership responsibilities.

Visit Our Resource LibraryForklift Certification Exam FAQs

Not if you took your education seriously! You’ll be tested on safety standards and basic forklift knowledge on the written test, and your operational skills during the driving test.

You cannot become fully certified through an online-only program. The written portion of the forklift operator test can be taken online by an OSHA-approved program, but the hands-on evaluation must be done in person, monitored by a certified evaluator.

Most providers require a 70% or higher on the written portion and a successful practical evaluation.

Don’t fret if you don’t pass the forklift certification test the first time around. You can always retest after some additional training and re-evaluations from your employers.

A forklift operator test can take between an hour to two hours. The written test takes 20–30 minutes. The practical test varies, but usually lasts 30–60 minutes.

Many OSHA-authorized trainers offer prep courses. Some employers also offer training ahead of evaluations.